Naturally, for businesses who produce physical objects, Industry 4.0 requires them to get to grips with a whole new culture, the digital one.

The digital culture can be harnessed to:

- interconnect stakeholders within value chains,

- distribute relevant information through these chains,

- significantly improve the availability of manufacturing resources through the Internet of Things and augmented intelligence,

- optimise resources and supply chains intelligently ,

- develop new sources of income in the form of associated services, while managing increasing levels of complexity .

However, it is essential to rethink the agility and efficiency of the production tool, the risk otherwise being that the promise of the Industry 4.0 might remain just a theory.

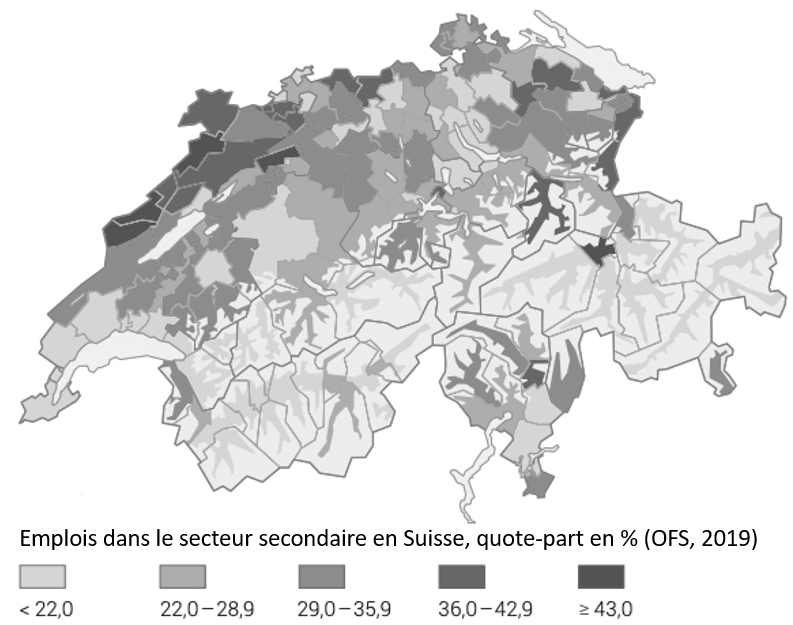

The industrial history of Switzerland shows that manufacturing firms have managed to preserve their know-how and adapt continuously, resulting in a secondary-sector employment rate of up to 50% in the Jura Arc Region. And yet the industry does not enjoy favourable conditions; it suffers from high salaries, no natural resources, a lack of space, and a safe-haven currency that regularly reduces earnings, as these rely mainly on exports.

But Switzerland has genuine advantages. One of the keys to this industrial revolution is interconnection, and with the country’s compact size placing all stakeholders in close proximity, it is much easier for the stakeholders in any one value chain to come together whenever necessary. The revolution also requires a cultural shift, from a culture of secrecy to one of sharing whatever can and should be shared, and to one that embraces the “community of interest”.

And while humility is undeniably one of our strengths, it must not stop us from showcasing our successes; we can be legitimately proud of our know-how and achievements.