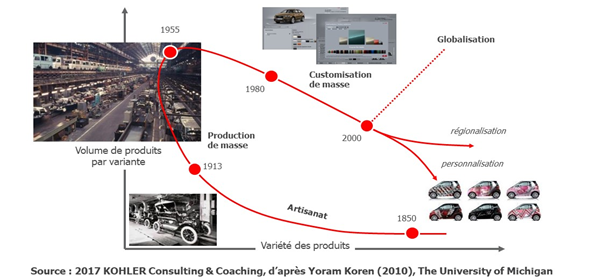

Throughout two centuries of industrialisation, the prevailing strategy has been to imagine what the end user might consume, to overproduce stock at all stages of manufacturing and distribution, and to push the products towards potential customers with copious advertising and promotion.

The concepts of digitalisation that have swept through businesses in recent years under what is called “Industry 4.0” have certainly led to a rethink of manufacturing processes. This is particularly true for products with high added value that intrinsically call for customisation.

So why not consider reversing the value chain? If we were to start with the end user and work backwards to the last of the necessary subcontractors, with a “C2B2B” (Customer-to-Business-to-Business) business model, not only would all stakeholders be interconnected but also they would serve a citizen-consumer, who would trigger on-demand production based on their own needs. It is the advent of the customisation industry and a de facto return to mindful consumption: a 21st-century version of the craft industry.

The luxury, watch-making, jewellery, medtech, and prosthetics and implant industries, together with others such as top-of-the range connectors, are all constrained by increasingly small batch sizes and are consequently calling for more research into the potential of Industry 4.0. This type of production would integrate the differentiating factors desired by the end customer to satisfy either a wish or a need, and would guarantee the high added value needed by Swiss manufacturing in the long term.

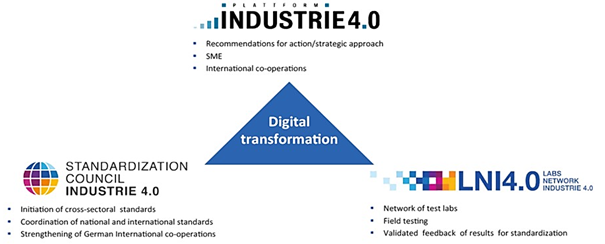

For the last ten years, Germany has been nurturing “smart factories” (Labs Network Industrie 4.0) to convince industry of the potential of this revolution. These experimentation centres address topics related to regional know-how and aim to give SMEs and mid-market companies somewhere to develop standards after accepting and appropriating the digital transformation concepts that have been rolled out and shared.

The goal of the MicroLean Lab is to create an experimentation center of this kind, adapted to the Swiss microtechnology industry.